Your cart is currently empty!

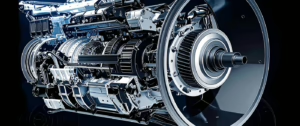

When most people think about what keeps a truck moving, they picture engines, transmissions or differentials. But there’s another component that is absolutely essential, making power transfer possible across the entire driveline: the universal joint, or U-joint.

From the early days of mechanical engineering to today’s heavy-duty commercial trucks, the U-joint has been the link holding everything together. Its genius lies in its simplicity: a mechanical connection that allows power to flow smoothly between rotating shafts at different angles, maintaining motion even when alignment is imperfect or constantly changing.

A Brief History: From Cardan to Cross and Bearing

The universal joint traces its lineage back to the 16th century, when Italian mathematician Gerolamo Cardano described a flexible coupling capable of transmitting rotary motion between misaligned shafts. His concept, later known as the Cardan joint, was used in everything from early clock mechanisms to horse-drawn carriages.

In the early 20th century, as the automotive industry boomed, engineers refined Cardano’s design into what we now recognize as the cross and bearing style U-joint. This modern version introduced needle bearings and hardened trunnions for smoother operation, longer life, and greater torque capacity — ideal for trucks and industrial machinery that demanded durability under extreme conditions.

How a U-Joint Works

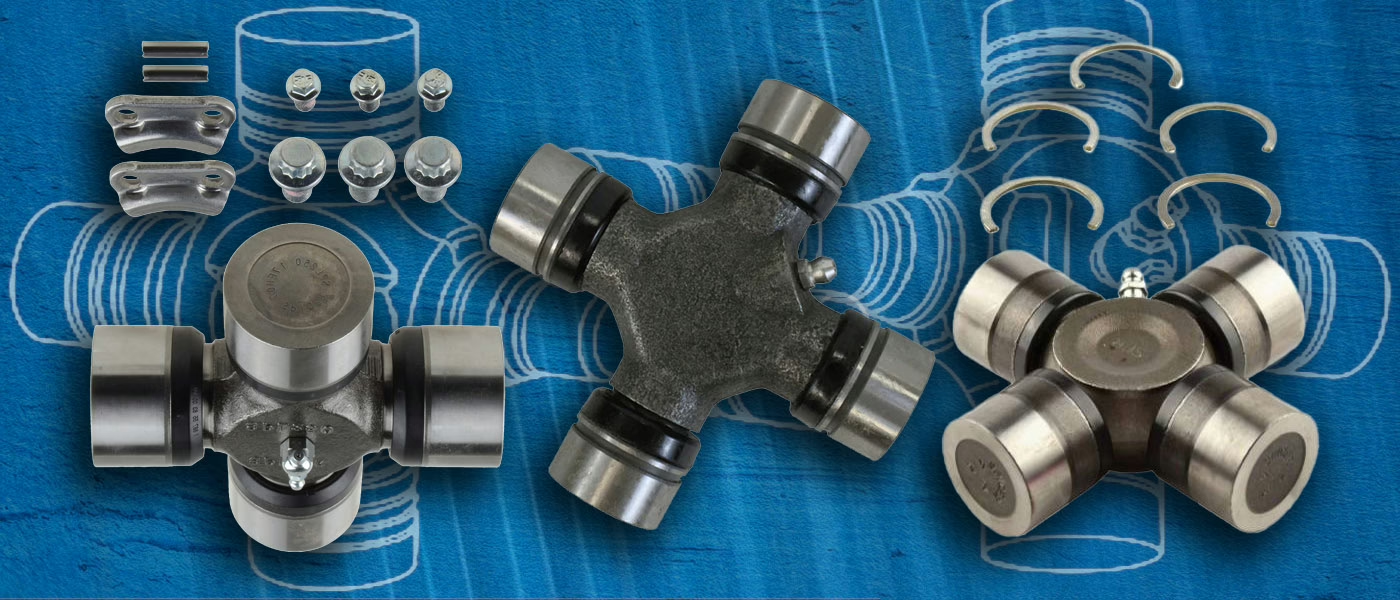

A universal joint connects two rotating shafts that are not in a straight line, typically at the driveshaft ends where angles constantly shift due to suspension movement or load conditions. It consists of:

- Cross (spider): The central X-shaped component that transfers torque between shafts.

- Bearing caps and needle bearings: Reduce friction as the joint rotates at variable angles.

- Yokes: Fork-like ends on the driveshafts that attach to the cross via bearing caps.

- Grease seals and zerk fittings: Keep lubrication in and contaminants out.

The U-joint allows for smooth transmission of rotational power while accommodating up-and-down or side-to-side motion, critical in a heavy-duty truck where axles flex under load or over rough terrain.

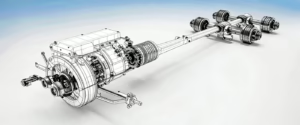

Role in a Heavy-Duty Truck Driveline

In a heavy-duty truck, U-joints are used throughout the driveline to transmit torque from the transmission to the axles while maintaining flexibility. Typical placements include:

- Transmission output to driveshaft input

- Intermediate shafts between carrier bearings (in multi-section drivelines)

- Driveshaft to differential input (pinion yoke)

Each joint compensates for movement caused by suspension articulation, frame twist, or driveline angle changes — ensuring that power delivery remains constant and vibration-free.

In multi-axle configurations (6×4 or 8×6), multiple U-joints are required to connect power dividers and inter-axle shafts, maintaining precise phasing and alignment to prevent vibration and premature wear.

Common Types of U-Joints in Heavy-Duty Applications

- Cross and Bearing (Conventional): The most common type; uses a central cross with capped bearings.

- Double Cardan Joint: Two U-joints coupled by a center yoke to reduce angular velocity variation; used in applications with steep operating angles.

- Constant Velocity (CV) Joint: Maintains uniform rotational speed between input and output; often found in front-wheel-drive systems and select heavy-duty steering or PTO applications.

Popular U-JOINT Manufacturers and Series

Several manufacturers have become synonymous with reliability and innovation in heavy-duty U-joint technology:

Spicer (Dana Incorporated)

The industry benchmark. Spicer U-joints are found in countless OEM and aftermarket applications. Popular models include:

- Spicer Life Series (SPL) – Premium sealed joints for extended life and maintenance-free operation.

- Spicer 10 Series – A long-standing industry standard for heavy-duty driveshafts.

- Spicer 170, 1710, 1760, and 1810 series – Commonly used in Class 6–8 trucks.

Meritor

Meritor’s RPL (ReadyPack Life) series provides a permanently lubricated, sealed-for-life design that eliminates maintenance downtime. Their Permalube™ cross bearings also extend service intervals for fleet operations focused on uptime.

Fabco and Eaton Fuller

While best known for transfer cases and transmissions respectively, both rely on precision-engineered U-joint assemblies in their driveline systems, ensuring consistent torque transmission under extreme duty cycles.

Maintenance and Service Considerations

Even the strongest U-joint will fail without proper care. Signs of a failing U-joint include:

- Clunking or metallic noise during shifts or acceleration

- Vibration or driveline shudder at speed

- Visible rust near bearing seals or loss of lubrication

Preventive maintenance tips:

- Regular greasing (for serviceable joints) using high-quality lithium-based grease.

- Inspect yokes and retaining clips for looseness or corrosion.

- Replace worn joints immediately — failure at highway speeds can cause catastrophic driveline damage.

The Heart of a Moving System

The universal joint is more than a simple connector, it’s the pivot point of motion that allows a rigid mechanical system to behave organically, flexing and adjusting to the demands of real-world driving. In a heavy-duty truck, it carries the heartbeat of torque from engine to wheels, enduring millions of rotations under punishing conditions.

As trucks become more efficient and powerful, U-joint technology continues to evolve, with stronger materials, precision balancing, and maintenance-free designs ensuring that this centuries-old invention remains indispensable in the modern era of transport.

At General Truck Parts, we stock a full range of Dana Spicer, Meritor and Eaton Fuller U-joints and universal joint assemblies for all makes and models of heavy-duty trucks. Whether you’re maintaining a single vehicle or managing a fleet, our driveline experts can help you identify the correct joint series and keep your truck running smoothly for the long haul. Contact us today to find the part you need.

Recent Knowledge Base Articles

Contact Us Today

Our Experts are available to answer your questions and help you with your needs.

We take pride in getting you your answers, parts, and assemblies fast.

| 800-621-3914 |